What is solid lubricant ?

Currently, reduction in sliding resistance and lowering of friction resistance of industrial components are accomplished through wide use of lubricant application, which includes forming wet-type lubrication film wherein oil or grease is applied and dry-type lubrication film wherein resin coating containing solid lubricating film is applied through baking finish or plating.

The former is a known lubrication system, which has traditionally been used, and although the performance of oil and grease has improved with additives, etc., due to the requirements of quick movement and wear-resistance improvement of products, there are increasing cases of transition into the latter, dry-type lubrication film due to environmental concerns and limitations in areas in which it can be used.

A solid lubricant is used for the dry-type lubrication film and the solid lubricant generally consist of molybdenum disulfide, graphite, PTFE (polytetrafluoroethylene), etc. It is characterized by extremely high load carrying capacity and low friction coefficient as shown in the table.

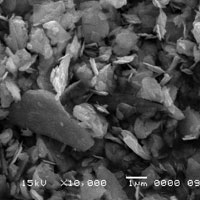

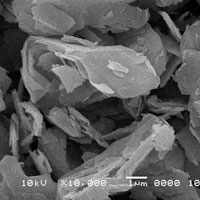

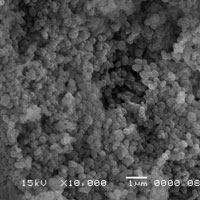

Further, when observing above lubricants under electron microscope, they are spark shaped and skidding occurs when load is applied, which leads to low friction.

Characteristics of Solid Lubricant

| 固体潤滑剤 | 外観 | 密度 | 摩擦係数 | 耐荷重性 | 耐熱性 |

|---|---|---|---|---|---|

| 二硫化モリブデン | 灰銀色 | 4.8 | 0.04 | 784Mpa | 350℃から徐々に酸化(MoO3) |

| グラファイト | 黒色 | 2.2 | 0.06 | 490Mpa | 550℃から徐々に酸化(CO2) |

| PTFE | 白色 | 2.2 | 0.04 | 196Mpa | 300℃前後より熱分解生成物発生 |

SEM Image – Solid Lubricant