We provide evaluation test machines for research divisions of companies and apparatuses used in experiments and training at universities.

Test machines and inspection machines

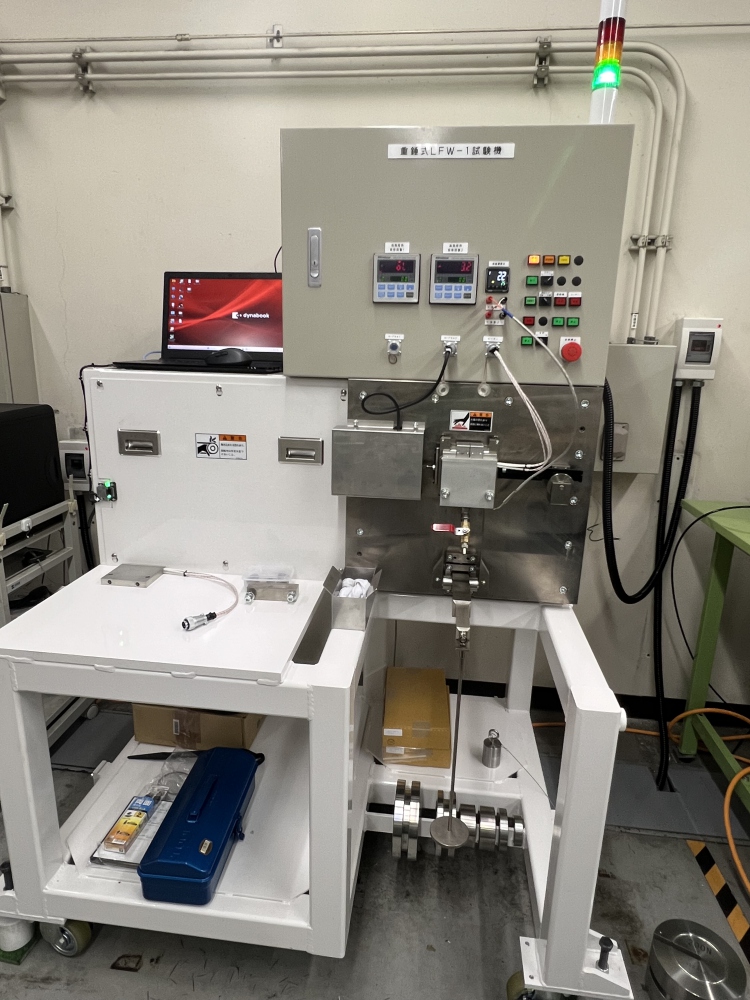

Weight-type LFW-1 Testing Machine

Tests the lubricity, pressure resistance, and durability of lubricating oils, lubricating agents, and solid film lubricants.

Conforms to ASTM D 2714 and JASO M358

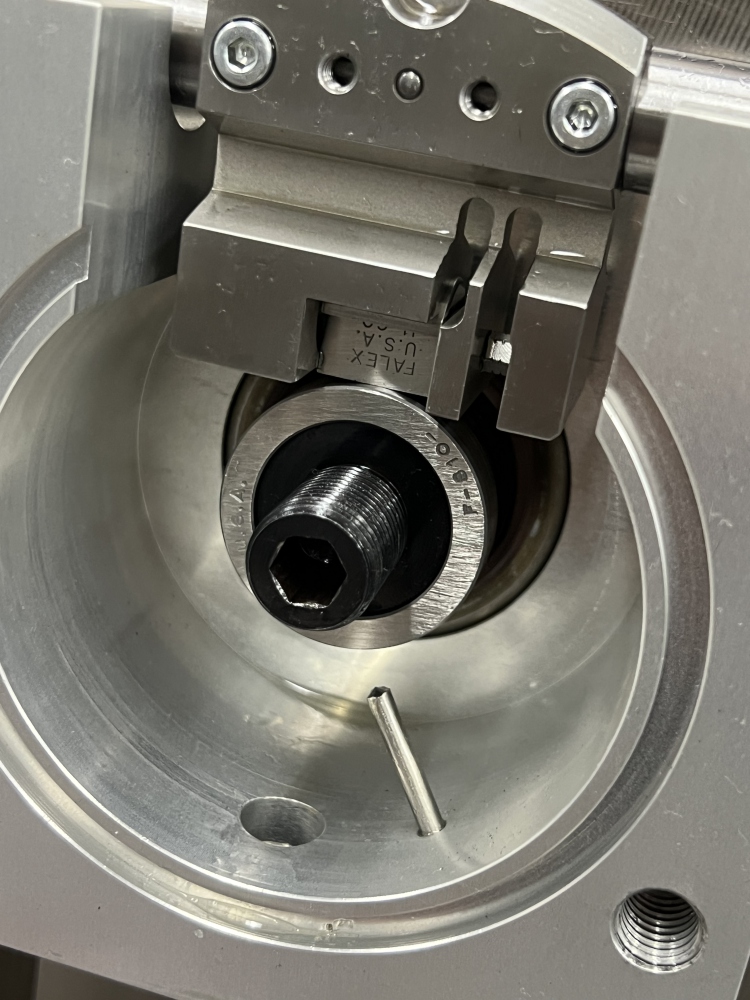

Testing section

A ring is attached to the main shaft and a block is secured in contact with the top of the ring.

By applying a load from the top of the block, the ring is rotated.

Electric cart torque test machine

Torque test machine used in training at engineering and electrical engineering departments.

Rear wheel measuring section

Small chassis platform is built on rear wheel and torque measurement for electric cart is performed.

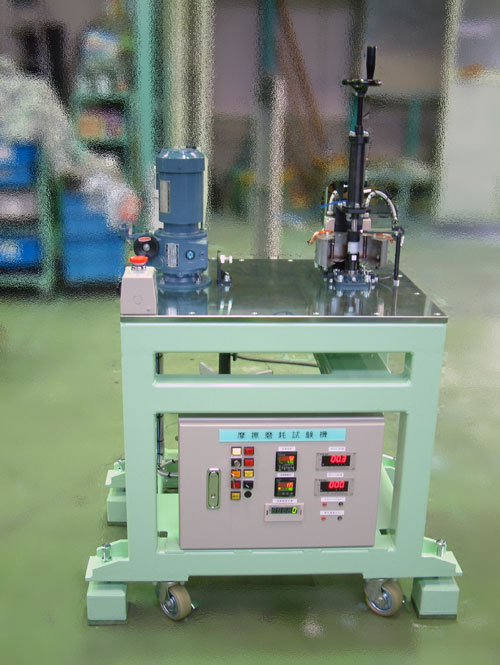

Frictional wear test machine

Surfaces of resins are coated with sample lubricant to measure frictional resistance under pressurized rotation.

Measuring section

Depending on the type of sample, frictional resistance under normal temperature and high temperature, or wear progression of resin is measured.

Low temperature torque test machine

Grease performance below freezing temperature is measured.

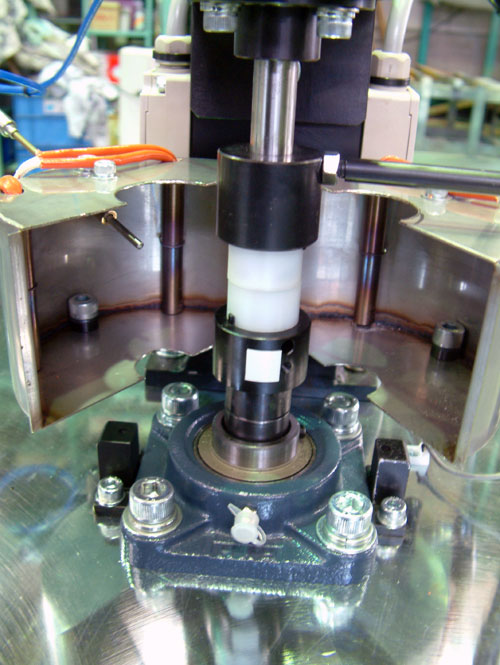

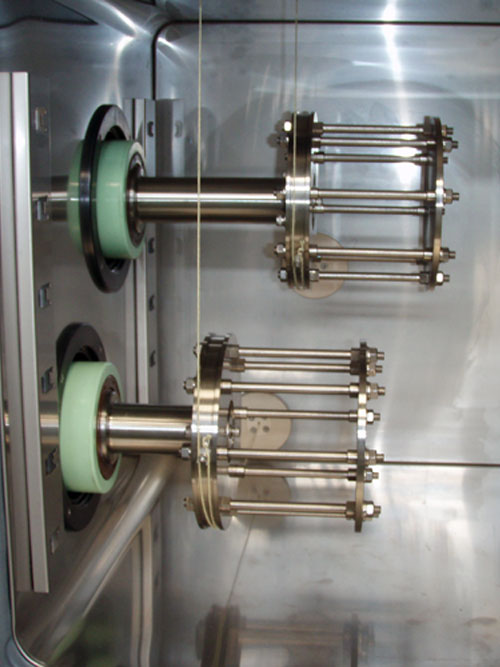

Inside of measurement low temperature tank

Grease resistance fluctuation within bearings set to jig is measured.

Bowden test machine

Coefficient of friction of lubricant film on the surface of sample is measured.

Back and forth sliding motion measurement section

Test piece is pressurized on sample surface to repeat back and forth sliding motion from which the fluctuation in frictional resistance value is measured.

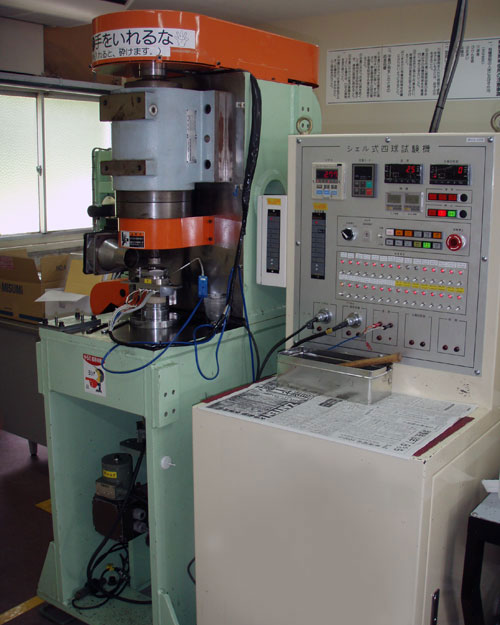

Shell-type four-ball extreme-pressure lubricant test machine

Two types, instant extreme pressure (EP) and long duration light load (WEAR), can be measured.

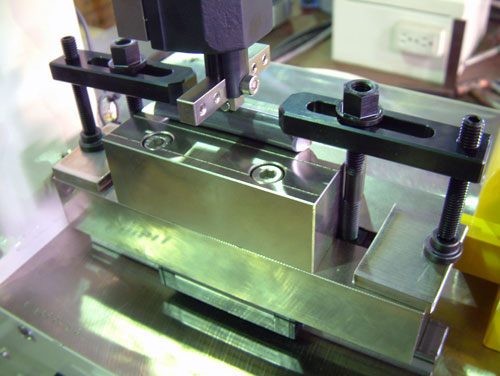

Measuring container and test piece

The wear mark and load carrying capacity of the test piece is measured by putting the sample grease or lubricant in the 3 hard balls of the test piece and adding load and rotation from above with hard balls.

High temperature bearing test machine

Grease degradation with high temperature range is measured.

In-tank double-linked bearing set jig component

10 pieces of bearings pressurized with jig is set to measure the status of grease degradation under high temperature and long duration.

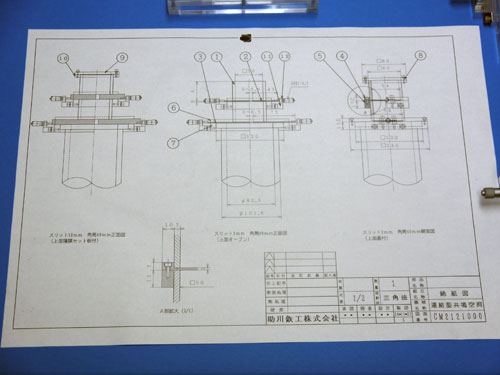

Resonance experimentation jig

Sound or resonance data is collected by adjusting the width and thickness of the slit.

Assembly diagram

Design was based on the request of a professor of engineering/mechanical engineering department.

Single handle 4-axis rotational bending fatigue test machine (existing)

An old test machine installed in the material dynamics lab of an engineering department.

Single handle 4-axis rotational bending fatigue test machine (modified)

An existing test machine from the lab was overhauled.

Existing/test piece set component.

The existing test piece set component was a method of holding the test piece down from the outside with a set bolt, but the occasional loosening prevented stable data.

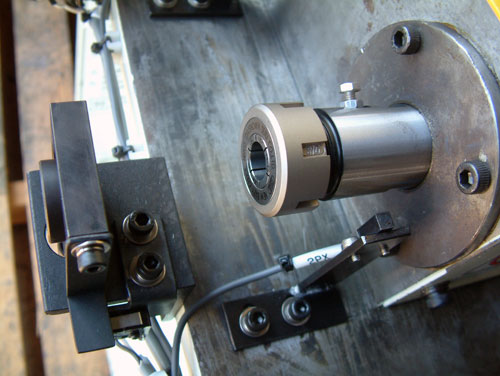

Modified/test piece set component

The spindle shaft was newly created to switch over to the collet chuck method.

As a result of switching the collet sleeve, test pieces with different diameter can be set.

Spark unit performance inspection apparatus

Inspection line to perform continuous inspections of electrical current, voltage, and waveform of the spark unit all the way to packing.

Small back and forth sliding motion test machine

Measures, through back and forth sliding motion, the frictional resistance of the sample under light load.